Front vs. Rear Brakes: Does it Even Matter?

If you have ever needed to repair the brakes on your vehicle, you may have observed that the front brake pads are often the ones that wear out the fastest. This is even though the majority of current automobiles are constructed with brakes on all four tires. Even though this is a fully natural occurrence, you may be intrigued about the variations that exist between the front and rear brakes, as well as the impact that these variations have on how your vehicle comes to use.

Do the front brakes or the rear brakes make a difference? All four brakes indeed play a significant part in bringing your vehicle to a halt; nevertheless, the front brakes are the ones that are responsible for the majority of the force that is applied to the vehicle when it comes to coming to a stop. The front brakes are often responsible for providing anywhere from sixty to ninety percent of the friction that is necessary to slow down the vehicle. More recent automobiles, on the other hand, will distribute energy to all four tires in a manner that is more uniformly distributed, depending on the bias of the brakes.

There is a lot of intricacies involved in even the relatively basic operation of bringing a vehicle to a stop, even though the minute details of the procedures that enable your automobile to work effectively are in many cases entirely forgotten about. Although not every person who owns a car will be interested in learning how everything operates, those who are knowledgeable about how their vehicle operates are in a better position when it comes time to do maintenance and repairs to the vehicle. When it comes to those brakes…

For a car, the brakes are either at the front or the back.

These days, disc brakes are installed on every one of the four wheels of every contemporary automobile. However, the broad application of four-wheel drive braking systems did not become conventional until the later part of the twentieth century. However, by the 1980s, almost every automobile that was made would have drum or disc brakes, or a combination of the two, on each of the four wheels.

The advantages of hydraulics would not be realized by the ordinary customer until far into the 1940s, even though automobiles with a four-wheel hydraulic braking system had been designed by the year 1918. To a large extent, this is attributable to the fact that the Ford Motor Company and General Motors did not begin using hydraulic four-wheel brakes as a standard until after World War Two.

However, from a practical standpoint, the front brakes on contemporary cars often perform most of the heavy lifting when it comes to bringing the automobile to a stop. As a result, the front brakes of a car typically get more attention and care than other parts of the vehicle.

To put it another way, the brakes that are going to be the most significant are going to be the ones that are located in the front of your vehicle. However, this does not mean that the brakes at the back of your vehicle are not vital. Many modern automobiles depend more heavily on all four brakes to disperse energy more equally.

The front brake and the back brake are two different types of brakes.

Where the front and rear brakes are located on a vehicle is by far the most noticeable distinction between the two types of brakes. A vehicle’s front brakes are located at the front, while the rear brakes are located in the back. It is important to make this difference, even though it could seem to be unnecessary to say it. As a result of their distinct locations, each of them performs a somewhat different role.

Even though your vehicle may employ the same kind of braking system on both the front and rear tires, how the two sets of brakes manage the transfer of energy when the vehicle comes to a stop will be different.

It is more of an issue of physics than anything else since the actual differences between the front and rear of a vehicle become apparent when one considers how they cope with the friction and heat that it generates while the braking system is in operation.

Because the front brakes of a vehicle produce a much higher amount of heat compared to the rear brakes, the structural variations that are more observable between the front and rear brakes become more apparent when one examines the design of the brakes.

The front brakes of your vehicle

It is because of Newton’s first rule of motion that we are aware that an item that is moving has the desire to continue moving. Putting this into the context of an automobile, it implies that when you apply the brakes to come to a stop, the center of gravity of the vehicle will move and shift forward. This causes a considerable increase in the amount of downward force that is applied to the front tires, which in turn requires a greater amount of braking effort. As a result, the front brakes experience a much higher level of friction, which results in an excessive amount of heat.

Depending on the speed at which the vehicle is moving, the front brakes of a vehicle may go through temperatures that can reach up to 500 degrees Fahrenheit. Because of this, the most obvious difference between the front and rear brakes is the fact that the front brakes have to be much thicker and heavier than the rear brakes to effectively disperse the heat that their counterparts generate.

Characteristics of the Front Brakes’ Design:

- Due to the additional braking power that is needed at the front of the car, the front brakes require a larger amount of hydraulic pressure to be divided by the master brake cylinder to create a bigger clamping force on the tires. This is caused by the fact that the front brakes are responsible for braking the vehicle.

- Multi-piston Brake Calipers That Are Bigger: Once again, because of the need for more braking force, the brake calipers that are located at the front of a vehicle are built to be bigger and have a greater number of pistons. This is done to ensure that there are fewer points of failure and a greater surface area for heat transmission.

- Moreover, the brake pads on the front brakes are bigger than those on the rear brakes. These bigger brake pads not only have a greater surface area, which allows them to absorb more heat, but they also have a greater frictional effect on the rotor.

- Material for More Aggressive Braking Pads It is also extremely typical for the front brakes of a vehicle to employ a material that is more aggressive for its braking materials. This helps to impart more friction to the rotor, which in turn helps to bring the car to a stop more quickly.

- In today’s world, the brake rotors that are positioned at the front of a vehicle are intended to have a wider diameter than the ones that are located at the back of the vehicle. The purpose of this is to increase the amount of stopping torque that is available when the brakes are engaged.

- Brake Rotors That Are Much Thicker The front brake rotors of modern vehicles are likewise engineered to be far thicker than the rear brake rotors. To ensure that the front brake rotors can keep their form even when exposed to high temperatures, this is required.

- Rotors for the front brakes that are vented: In contrast to the rotors for the rear brakes, several automobiles are manufactured with ventilated front brake rotors. The extra ventilation provides the rotors with another effective way to dissipate the heat caused by hard braking. Aerodynamic

- Body Features: A majority of modern vehicles also implement aerodynamic features in the chassis of a car which helps direct air through the front brakes to provide extra heat dissipation when the car is at speed.

The Rear Brakes of Your Vehicle

while compared to the brakes that are placed at the front of your vehicle, the ones that are positioned in the back of your vehicle are almost usually built to be able to endure much lower temperatures and are typically constructed to be subjected to less stress while functioning. In addition, this is the reason why the brake pads that are located at the front of your vehicle are often the first ones to need replacement.

The rear brakes of a car can never produce more than forty percent of the stopping force, even though the braking bias of different cars might vary quite a little from one another. The reason for this is to prevent the rear brakes from locking up or otherwise causing the Anti-lock Braking System (ABS) to activate continuously. Rear brakes must have the following design aspects to ensure that the braking system as a whole is adequately stable.

Design Requirements for the Rear Brake:

- Hydraulic Pressure That Is Low The brake master cylinder will always divide the hydraulic pressure that is delivered to the rear brakes of your vehicle at a considerably lower pressure than the rest of the system. Because, as was said before, rear brakes do not need as much braking force, this is done to accommodate them.

- Smaller Calipers: In contrast to the brakes in the front of the vehicle, the brakes at the rear of the vehicle employ smaller calipers. There is less heat and friction produced as a result of these smaller calipers since they exert less clamping force on the rotors.

- In addition to the smaller calipers, the rear brakes also employ smaller brake pads to lessen the amount of friction that is occurring on the rotor. It is common practice to choose a material that is less harsh when making rear brake pads.

- Smaller brake Rotors You may have noticed a pattern developing here, as the brake rotors on the back of a car are manufactured to have a smaller diameter than their counterparts at the front of the vehicle. Rotors with a smaller diameter have a lower stopping torque than larger ones.

- Brake Rotors That Are Thinner The rear brake rotors of a vehicle are not only smaller, but they are also thinner. This is because the back brakes of a vehicle face a much lower level of heat. In addition, there is never a typical circumstance in which the rear brakes are subjected to a level of stress that would lead to the need to ventilate the rotors.

- Economy Drum Brakes: Even though the technology is somewhat old, a significant number of automobiles offering more affordable prices will employ drum brakes for the rear of the vehicle. Drum brakes are an inexpensive and efficient alternative to disc brakes, which are more costly, yet they provide all of the same advantages as disc brakes. This is because the rear brakes on a vehicle are meant to be manufactured to a lesser specification anyhow.

There are a lot of similarities and variations between the front and rear brakes that are parallel to each other, as you can see via the comparison. Both sets of brakes perform the same purpose; however, they manage the transfer of energy in their distinct methods to guarantee that the ride is safe and stable for the driver. Although they both perform the same function, they do it in different ways.

Comparing Disc Brakes vs Drum Brakes

The age of the technology is likely the most straightforward way to differentiate between disc brakes and drum brakes, even though the designs and mechanisms for braking are relatively unique from one another.

Even though drum brakes and disc brakes were both developed in the early years of the twentieth century, it was not until well into the 1940s before disc brakes were widely used in consumer automobiles. These days, the majority of automobiles are equipped with improved disc brakes on each of the four tires.

The most evident physical differences between the disc brake and the drum brake become apparent within minutes of gazing at them. This is because the disc brake and the drum brake both use completely distinct systems to supply stopping force to the tires of a vehicle.

Brakes on the Drum

In the year 1900, the technology of drum brakes was first used on a vehicle manufactured by Maybach. These early drum brakes were mechanically actuated by a combination of levers, rods, and cables. These components were responsible for controlling the “shoes” that were pressed against the inside of the drum.

By 1930, however, the majority of drum brakes would employ the oil pressure within a tiny wheel cylinder in conjunction with a set of pistons to execute braking inside the drum. This was before the advent of the hydraulic brake.

Many components go into the construction of drum brakes.

- Additionally referred to as the “Torque Plate,” the backing plate serves as a foundation for all of the other components. Its name comes from the fact that it is responsible for absorbing the torque that is generated while the vehicle is braking. It is not only responsible for supplying the bulk of the house’s structural integrity, but it also safeguards the remaining parts of the housing from dust, debris, and other foreign materials.

- It is common practice to construct the drum portion of a brake drum out of a particular kind of cast iron, which is more resistant to the effects of heat and wear. During the rotation of the vehicle, the drum spins in tandem with the wheel and axle. By applying pressure to the inside of the drum, the brake lining can generate friction, which in turn causes the wheel to slow significantly.

- Cylinder for the Wheel: Each wheel drum has a single wheel cylinder for usage. It is the hydraulic pressure that originates from the master cylinder that causes the pistons to move outward. This pushes on the main brake shoe and drives it against the inside of the drum, which results in the friction that is necessary to prevent the tires from rotating.

- Brake Shoe: Brake shoes are normally constructed by welding together two pieces of steel to produce a crescent-shaped component. Brake shoes are used to apply and apply brakes. Every drum has two shoes, a main shoe and a secondary shoe, which together create a circle within the drum. Every drum has two shoes. When applying a high friction brake lining to the outside of the crescent shoes, adhesive or rivets are the methods of choice.

The Disc Brakes

Even though the first concepts for disc brakes date back to the late 1890s in England, the Lanchester Motor Company was the first company to produce a disc brake system that had practical applications in 1902. Even though the actual discs were considerably smaller and required cable operation, this early disc brake functioned in a manner that was quite similar to that of current disc brakes.

Nevertheless, the technology of disc brakes would not become widely available for use in consumer automobiles until the middle of the 1960s, which was more than half a century later.

Three of the most important components of a disc brake are as follows:

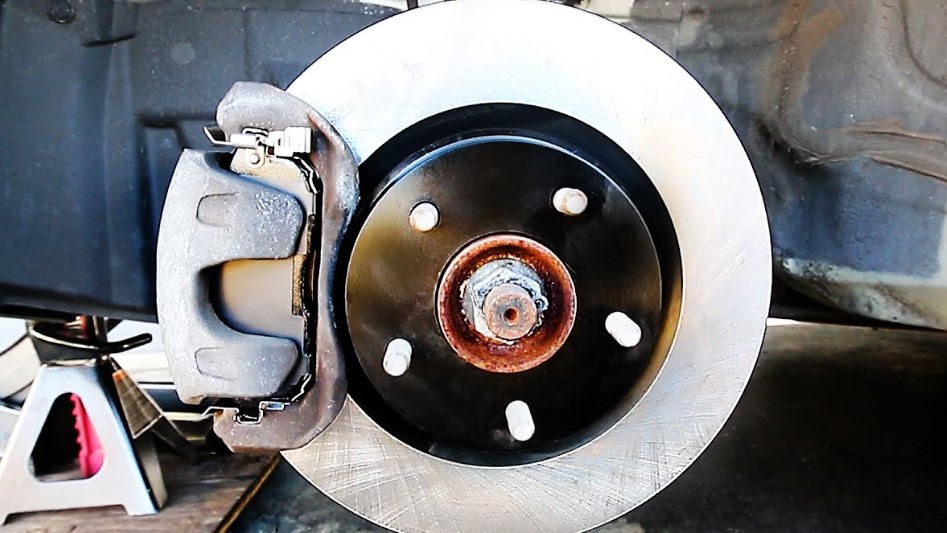

- Element of a disc brake that is connected to the axle of a vehicle is called the rotor. The rotor is the “disc” element of the disc brake. A type of metal mound that the tires are fastened to is referred to as the “hub,” and it protrudes from the side of the rotor that faces outward.

- Caliper: The calipers on a car’s disc brake operate somewhat similarly to the calipers on a bicycle brake, with several deviations. However, there are a few key differences between the two. A hydraulically powered piston that is attached to the calipers allows the clamp to push on either side of the rotor when the brakes are applied. This is analogous to the way that the calipers on a bicycle squeeze against the tires of the vehicle.

- In a manner that is analogous to the brake lining of a drum brake, the pads of a disc brake are constructed from a material that is resistant to heat and has a high friction coefficient. It is possible to connect these pads to each inside side of the brake calipers using glue or by using other ways. Calipers are responsible for applying pressure to the brake pads so that they are in contact with the rotor. This is what causes the friction that is necessary to slow down the wheels.

Disc brakes are the apparent victors when it comes to lifespan and dependability, even though drum brakes and disc brakes each have their own set of advantages and disadvantages that are unique to themselves.

The vast majority of contemporary automobiles are manufactured with disc brakes installed on all four wheels. These brakes are not only more durable, but they are also considerably simpler to maintain and repair if they get worn out.

Nevertheless, there are still a great number of budget vehicles, in addition to older automobiles, that continue to depend on drum brake technology as a comparatively more cost-effective alternative. Although there has not been a significant change in the fundamentals of drum brakes in more than a century, the wonders of contemporary engineering have made it possible to almost eradicate the issues that were previously associated with their current application. These problems include brake lockups and other deficiencies.

It is quite improbable that we will see any significant advancements that leave these systems obsolete, regardless of whether your vehicle employs a drum or a disc. Therefore, unless you are suffering from braking problems, you may as well not be concerned with the specifics.

Even more brakes!

Even though you may not have been aware of it, the world of brakes is a big and sophisticated realm that has a great deal more subtlety than even the typical motorhead would take into account. Even though this article does not cover all there is to know about the braking systems of vehicles, we hope that it manages to shed some light on some of the most fundamental ideas that are associated with braking.

If, for some reason, you are still not satisfied and would like to learn more about the history of car brake development, or if you simply want to know more about how the brakes in your particular car work, we recommend that you search through the various car forums that are available on the internet or that you ask your local mechanic for more information.